How We Screen Print

Screen printing—what is that?

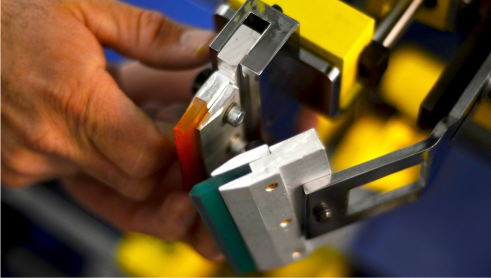

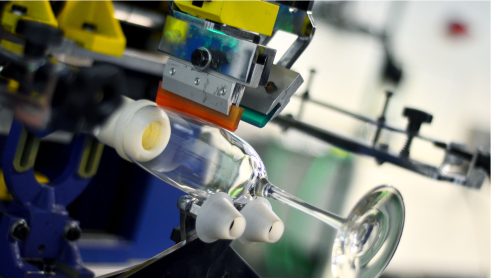

Forcing ink through a high-tension mesh screen onto an object is the customization technique known as screen printing. A screen is made with the exact design to be printed. The printing process forces each glass up into the screen while a squeegee blade pushes ink through the permeable screen and onto the glass surface. This decorating method allows for the lowest costs on larger sized orders.

Why do printed orders have a setup fee?

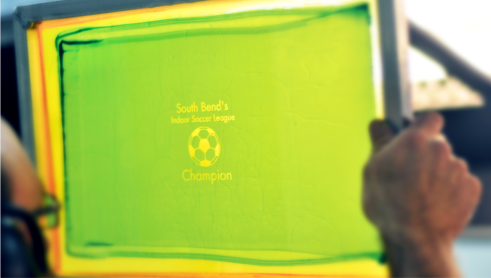

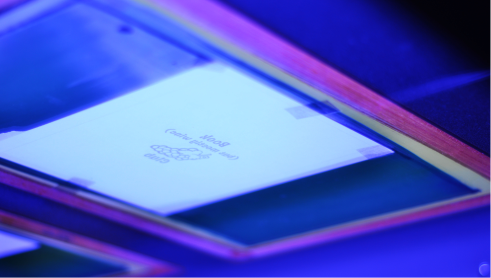

Individual screens have to be created for each color used for a printed order. A double-coated layer of emulsion is first laid onto the screen. The design is then laid on top and exposed using a metal halide lamp. The screen must then be washed out and dried. Due to the significant amount of time and material cost it takes to create screens, companies like ours must charge a setup fee. For decorating options with no setup fee required, please consider our engraved or digitally printed glasses.

What type of ink is used during screen printing?

Ultraviolet inks (UV) are the newest technology in screen printing, and they cure via exposure to intense UV lamps. Not only do these inks produce a superior and more durable print, but they are also more environmentally friendly than traditional solvent inks which dry via chemical evaporation into the air.

What colors can I get screen printed?

We offer 12 standard colors for printing, but if you wish to have a specific color just let us know—give us a general description like "light purple" or a Pantone color code and we can replicate it. Please note that we cannot print any neon or metallic colors, and not every Pantone color is possible with our process. If we are unable to print your design in your chosen color, we will contact you to discuss other options before beginning production.

How detailed can my design be?

With screen printing, we can achieve a high level of detail. Our process allows for full reproduction of complex designs, including graphics and fine text.

Will my printed design last forever?

While no such printing is truly permanent, our screen printing method produces very durable results. Each glass is flame pre-treated for optimum ink adhesion. Our UV inks lead the industry in survivability and durability. These inks will typically last for hundreds of cycles through a home dishwasher. Like with all such printing, heavy use or mechanical abrasion may eventually cause the ink to chip or wear away. For a truly permanent mark, please consider our engraved glassware.

Do I have to order a minimum quantity?

Because a screen's creation requires more time and labor to produce, we must require a minimum order size of 24 glasses for all screen printed orders. If you're looking for a lower quantity, we can engrave or digitally print smaller orders all the way down to one glass.

What if I want more than one color printed?

We can print single color designs on glasses using the screen printing method. If you are interested in printing multiple colors, please keep in mind that we also offer digital printing for cases where full color is desired.